WAGNER-Group’s Wagner Industrial Solutions Scandinavia operates in Finland, Sweden, Norway and Denmark. The head office is located in Sweden. Estolift TB OÜ is supplier of industrial surface treatment technology and the long term partner for Wagner.

We are pleased to announce the new technical updates of Wagner.

FASTEST AND AUTOMATIC: UNIQUE WAGNER SUPERCENTER PRO®

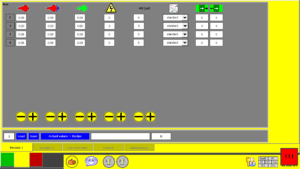

ALL SYSTEM CONTROLLED BY PLC

Rapidity:

Operator needed not specialized

Quality:

No possibility to make mistake

Efficiency:

Constant timing colour change

- Switch on machine:

- booth, bottom cleaning, recovery and final filter

- Input parameters recipes

- Application System

- Handling

- Base motorized

- Calling programs

- System on off guns

- Management vertical horizontal detection

- Consumption powder

- Industrial counter

the “WAGNER DATA” SOFTWARE PRODUCTION

AUTOMATIC START of colour changing process :

- Detected the plate

- Send input to start cleaning Supercenter

- No MANUAL intervention

INDUSTRIAL COST JUST IN TIME:

- Costs control of real consumptions in Kilos

- Lot production save in multiply version: powder, customer name, production name

- Counter ‘hour/production’

- Time stop for colour change

- Time stop for problem production

- Hook numbers painted

- Timing Maintenance: Counter ‘hour/production’ spare parts

- Detailed guide for operator (to check

- Technical manual of all system on screen (to check

- Operator panel with TOUCH SCREEN with symbols and clear instructions

- All data connected directly with Office by net-intern

SUPERCENTER EVO : PRODUCTIVITY BOOST

Automatic Colour change process

Container easy to inspect

Constant mixing virgin/recovery

Automatic changing of new powder box ®

Automatic cleaning container with sieve

the “WAGNER DATA” SOFTWARE PRODUCTION

AUTOMATIC START of colour changing process :

- Detected the plate

- Send input to start cleaning Supercenter

- No MANUAL intervention

WAGNER`s ALL INSTALLATION CONTROL MANAGE FROM TOUCH SCREEN

- Intuitive, easy maintenance, fast growing, individual setting.

- Very simple interface with operator Setting easy to reproduce, stored with recipes for different pieces

- Direct and reproducible relationship between application parameters and piece to be coated

- Powder coating perfect result with both standard with metallic or special powder

- Easy to understand and to use

- Fast recognition and setting accuracy

- Up to 50 programs, easy to set and store

- Control maintenance with the ‘advise’ system

No regulation from rack

EASY AND QUICK SYSTEM FOR APPLICATION SETTING

- Parameters Inserting working: point of inversion, speed and stroke

- Saving receipts

- Precise inversion

- Solid structure

- movement with gear belts high capacity

- long life

- Norms respect Safety

- Manual moving bases – STANDARD –

- Motorized moving bases with encoder with Vertical/horizontal detection system – OPTIONAL-

- All the colour change steps directly on the panel: simple because interactive

- Possibility to make mistake reduced at the minimum: all the operation writed ion PLC with ‘confirming’ bottom

- Colour change simple and sure

- The filter management is from touch screen: power, setting cleaning cartridges

- With the new system studied, it is possible, through pressure sensors, detectors, have on the video on how to get information on the action to be on damper (opening or closing) and, in relation to values, when to interview

- This allows an high efficient ‘ad hoc’ in every moment of aspiration situation, keeping always in high performance filtration without unexpected decays.

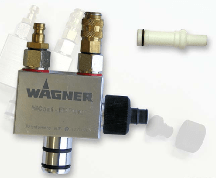

CONTROLLING APPLICATION PROGRAM FROM PLC via Module with AIR FLOW CONTROL with AFC

HD= High Density Pump

- Low purchasing costs

- Few components & only 1 wear part

- Fast & easy maintenance

- No daily service / check needed

- No mechanical wear of the powder material

- No blocking of powder hoses

ELECTROSTATIC GUNS (Corona) HIGH COAT PEA C4 XL

- Very simple interface with operator Setting easy to reproduce, stored with recipes for different pieces

- Powder coating perfect result with both standard with metallic or special powder

- Easy to understand and to use

- Fast recognition and setting accuracy

- Control maintenance with the ‘advise’ system

- No regulation from rack